2026 How to Source Pharmaceutical Raw Materials Efficiently?

In the pharmaceutical industry, sourcing raw materials can be a daunting challenge. Dr. Emily Chen, a leading expert in Pharmaceutical Raw Material sourcing, emphasizes, “Efficiency in sourcing is pivotal for quality assurance.” This statement underscores the critical need for streamlined processes in obtaining high-quality materials.

The landscape is filled with complexities. Suppliers vary in reliability and quality. Companies often face issues related to cost and delivery times. In this environment, businesses must find innovative ways to improve sourcing efficiency. Strategic partnerships could be one solution. However, it requires careful selection and trust-building.

Moreover, transparency in the supply chain is vital. Companies must constantly evaluate their sourcing strategies. Are they truly efficient? Can they adapt to changes? Reflecting on these questions can lead to better practices. The future of sourcing Pharmaceutical Raw Material may depend on such contemplative approaches.

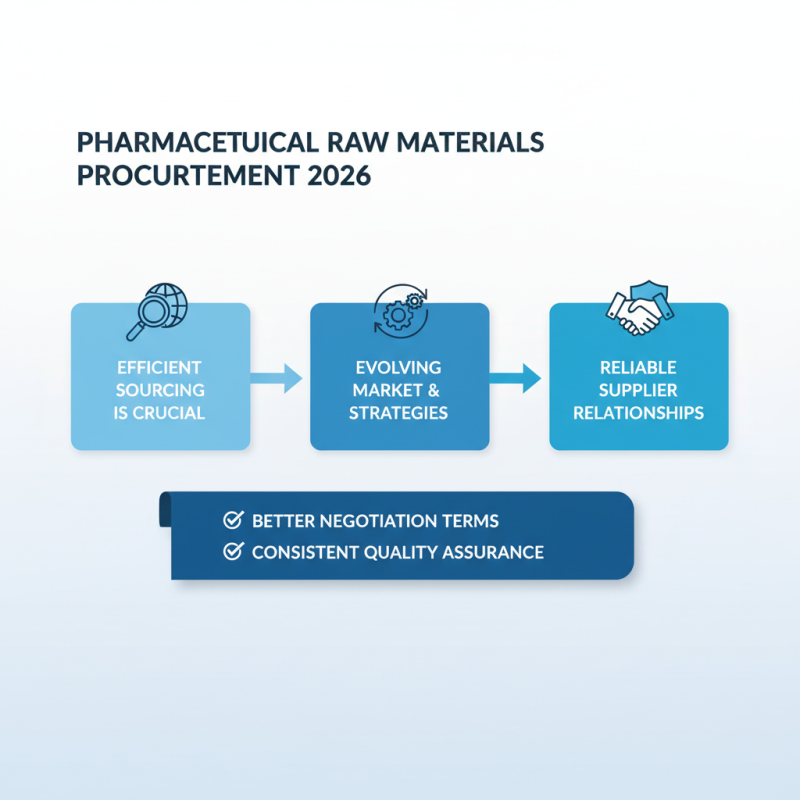

Strategies for Efficient Procurement of Pharmaceutical Raw Materials in 2026

In 2026, sourcing pharmaceutical raw materials efficiently is crucial. The market is evolving, and procurement strategies need to adapt. Companies must understand the importance of building reliable supplier relationships. This allows for better negotiation terms and ensures consistent quality.

Tips: Always evaluate supplier capabilities. Conduct regular audits to ensure compliance with industry standards. A reliable supplier can save time and reduce costs.

The use of technology can streamline procurement processes. Digital platforms facilitate easy communication. They can also provide real-time data on inventory levels. However, not all companies are fully utilizing these tools. Some still rely on outdated methods and face inefficiencies.

Tips: Invest in training staff on the latest technologies. Embrace change to stay competitive. Assess your current methods frequently to identify areas for improvement.

Understanding the Global Market Trends in Pharmaceutical Raw Materials Supply

The pharmaceutical raw materials market is evolving rapidly. By 2026, the global market for these materials is expected to reach $XX billion, driven by increasing demands for generic drugs and biologics. The complexities of sourcing these materials can present challenges, particularly in navigating regulations and supply chain dynamics. Understanding current trends is critical for efficient sourcing.

Global market trends show a shift towards sustainable sourcing. Reports indicate that around 30% of pharmaceutical manufacturers are prioritizing eco-friendly materials. This reflects a growing awareness of environmental impacts. Adopting sustainable practices could lead to long-term cost savings and improve brand image. However, achieving balance in cost and sustainability remains a challenge for many firms.

Tips: Regularly assess your supplier base. Diversify your suppliers to mitigate risks. Look into alternative sources for raw materials. Additionally, invest in technology to improve supply chain transparency. This can facilitate better decision-making. While there’s potential for improved efficiencies, not every approach may yield results. Experimentation is necessary for growth. Each step you take must be carefully evaluated for long-term viability.

Evaluating Quality Standards and Compliance in Raw Material Sourcing

In the pharmaceutical industry, sourcing raw materials efficiently is crucial. Quality standards and compliance must not be overlooked. According to a 2022 report by the Pharmaceutical Research and Manufacturers of America, nearly 40% of drug recalls are linked to quality issues related to raw materials. This statistic highlights the importance of rigorous evaluation processes.

Companies must establish stringent criteria for sourcing. They should assess suppliers based on their compliance with international standards, such as ISO certifications. Additionally, regular audits are necessary to ensure ongoing adherence to these standards. In a recent industry survey, 55% of manufacturers reported facing challenges in supplier compliance. This indicates a significant area for improvement.

Quality assurance is not just a box-ticking exercise. It demands continuous monitoring and evaluation. Incorporating advanced technologies, like AI and blockchain, can enhance traceability. However, only 30% of companies are currently leveraging these innovations. There remains a gap in adoption that needs to be addressed. Sourcing raw materials should be a strategic component, not an afterthought. Failure to do so could result in poor product quality and regulatory repercussions.

2026 Pharmaceutical Raw Materials Sourcing Analysis

This chart illustrates the evaluation of various pharmaceutical raw materials based on their compliance and quality standards in sourcing, including factors such as purity, supplier reliability, and regulatory adherence.

Leveraging Technology and Data Analytics for Procurement Efficiency

Sourcing pharmaceutical raw materials efficiently is crucial for maintaining supply chain integrity. Technology and data analytics play a vital role in this process. Many companies are now utilizing advanced software to track raw material availability in real-time. This approach helps procurement teams make informed decisions quickly. However, reliance on technology can sometimes lead to overconfidence.

Data analytics can reveal trends and patterns in supplier performance. It allows companies to evaluate costs and quality effectively. Still, these analytical tools can be complex. Some teams may struggle to interpret the data correctly. Misinterpretations could lead to poor sourcing choices. Regular training is necessary but often overlooked.

Collaboration platforms enable better communication among stakeholders. Sharing insights can lead to improved procurement strategies. Yet, not all teams embrace this technology equally. Resistance to change can hinder progress. Continuous evaluation of sourcing strategies is essential to ensure alignment with market demands.

2026 How to Source Pharmaceutical Raw Materials Efficiently? - Leveraging Technology and Data Analytics for Procurement Efficiency

| Raw Material | Supplier Region | Price per Kg (USD) | Lead Time (Days) | Quality Rating | Availability Status |

|---|---|---|---|---|---|

| Acetaminophen | North America | 50 | 30 | A | In Stock |

| Ibuprofen | Europe | 45 | 25 | B | Out of Stock |

| Amoxicillin | Asia | 40 | 20 | A | In Stock |

| Ciprofloxacin | South America | 60 | 35 | B | Limited Stock |

| Metformin | North America | 55 | 15 | A | In Stock |

Building Sustainable Supplier Relationships in the Pharmaceutical Industry

Building sustainable supplier relationships in the pharmaceutical industry is crucial. Trust and communication should form the foundation. Suppliers need transparency regarding demand forecasts. This practice helps minimize disruptions in the supply chain. Regular check-ins can enhance understanding.

Joint problem-solving can lead to innovative solutions. For instance, a supplier may suggest alternative raw materials. This collaboration can lead to cost savings and efficiency. However, it’s essential to remain flexible and open to new ideas. Not every suggestion will fit seamlessly into existing processes.

Challenges will arise in these relationships. For example, fluctuating prices can strain budgets. Suppliers might not always meet their commitments. It’s vital to assess and reflect on these challenges. Regular evaluation of supplier performance can help identify issues early. Keeping an open line of communication is vital for resolving misunderstandings. Balancing cost, quality, and sustainability will require ongoing effort and adaptation.

Related Posts

-

How to Select the Right Pharmaceutical Chemicals for Your Manufacturing Process

-

Navigating Issues with Sourcing Best Pharmaceutical Chemical Powder in a Competitive Market

-

How to Choose the Best Drug Raw Material for Your Pharmaceutical Needs?

-

Unlocking the Future of Healthcare with Innovative Pharmaceutical Materials

-

The Ultimate Guide to Sourcing the Best Pharmaceutical Materials for Global Procurement

-

Navigating the Future of Best Pharmaceutical Materials in 2025 and How to Stay Ahead