What is Raw Pharmaceutical and Its Importance in Medicine?

The pharmaceutical industry plays a crucial role in global healthcare. Raw Pharmaceutical materials are essential for drug development and production. According to the latest industry report by IQVIA, the global pharmaceutical market reached approximately $1.42 trillion in 2021. Raw materials are at the heart of this industry, driving innovation and ensuring effective treatments.

Raw Pharmaceutical refers to the basic compounds used in drug manufacturing. These raw materials can include active pharmaceutical ingredients (APIs) and excipients. In 2020, more than 60% of the total pharmaceutical manufacturing costs were attributed to raw materials. This highlights their significant impact on the overall cost structure. However, the sourcing and quality control of these materials remain challenging.

Quality control can be inconsistent. Some suppliers may not meet the required standards, leading to potential risks in patient safety. Furthermore, reliance on raw materials from various regions can complicate supply chains. A report from the World Health Organization emphasizes the need for robust regulations and monitoring in this area. Addressing these issues is crucial for sustaining advancements in medicine and ensuring patient well-being.

What is Raw Pharmaceutical: Definition and Overview

Raw pharmaceuticals refer to the active ingredients used in the production of medicinal products. These raw materials can be derived from natural sources or synthesized in laboratories. According to the Global Pharmaceutical Raw Materials Market Report, the market is expected to reach $200 billion by 2025, highlighting its substantial growth.

The production of raw pharmaceuticals is critical for various therapeutic applications. For instance, APIs (Active Pharmaceutical Ingredients) are essential in drug formulation. These ingredients often face quality challenges that can affect their efficacy. A study by the FDA indicated that 40% of drug recalls were linked to API quality issues. Ensuring high-quality raw materials can mitigate these risks.

Moreover, the sourcing of raw pharmaceuticals raises ethical concerns. Some raw materials are harvested in unsustainable ways. This practice can harm local ecosystems. The industry must consider these impacts. However, there is progress. A growing number of companies are adopting sustainable practices. They recognize the importance of raw pharmaceuticals in creating effective and reliable medicines.

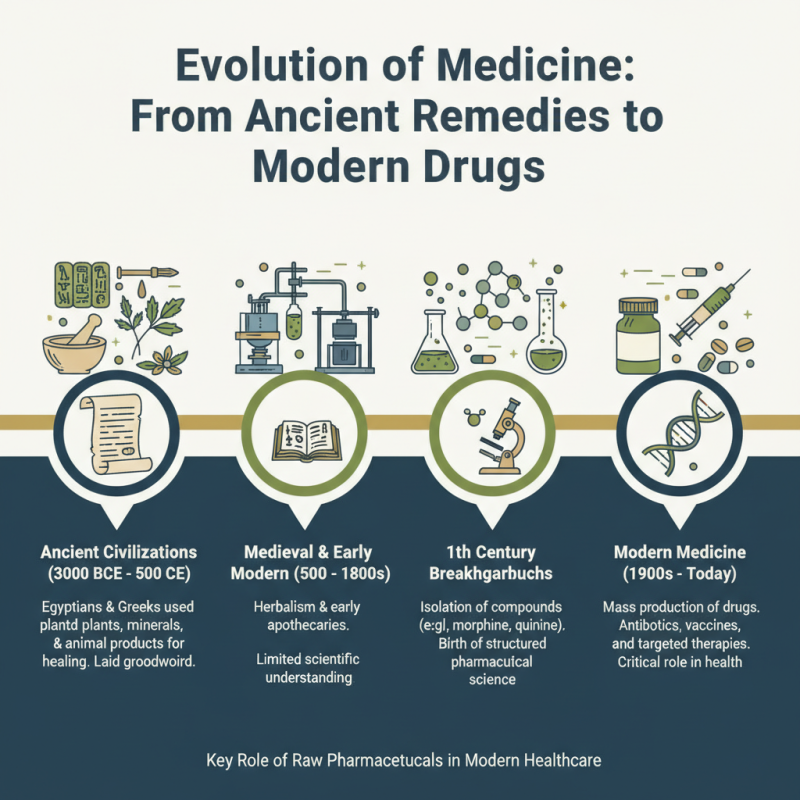

Historical Development of Raw Pharmaceuticals in Medicine

The historical development of raw pharmaceuticals reveals their critical role in modern medicine. Ancient civilizations, such as the Egyptians and Greeks, used natural substances for healing. They relied on plants, minerals, and animal products, laying the groundwork for today’s pharmaceutical practices. The transition from these rudimentary beginnings to more structured pharmaceutical science began in the 19th century. Major breakthroughs occurred with the isolation of compounds, leading to the development of powerful medications.

According to a report by the World Health Organization, 80% of the global population still relies on traditional medicines derived from natural sources. This reliance underscores the importance of raw pharmaceuticals today, as they provide essential medical solutions. However, challenges persist. Quality control is often inconsistent, leading to purity issues in natural products. Research indicates that less than 30% of herbal medicines meet the standards set for pharmaceutical quality. Such discrepancies highlight the need for ongoing improvements in production practices and regulatory frameworks.

The journey of raw pharmaceuticals is both inspiring and complicated. Despite their longstanding presence in medicine, ensuring efficacy and safety remains a crucial concern. Continuous research is necessary to enhance our understanding of these raw materials. The past teaches us about potential, but also reminds us of the need for vigilance in pharmaceutical development.

Key Types of Raw Pharmaceutical Materials and Their Sources

Raw pharmaceutical materials are the backbone of the drug manufacturing process. Their importance cannot be overstated. These materials include active pharmaceutical ingredients (APIs), excipients, and various intermediates that ultimately lead to effective medications. According to recent industry reports, the global raw pharmaceutical market is projected to surpass $400 billion by 2025.

Key types of raw pharmaceutical materials are diverse. APIs are derived from natural sources, such as plants and microorganisms. For instance, around 30% of all medications come from plant-derived substances. Excipients, which help in drug formulation, can be synthetic or derived from starch and cellulose. Interestingly, around 50% of excipients are sourced from plant origins. These materials ensure stability and bioavailability in pharmaceuticals.

Yet, challenges persist in sourcing raw materials. Quality control is critical; impurities can affect drug efficacy. The rise of drug-resistant strains adds another layer of difficulty. Regulations are strict, but there are still lapses in compliance. Proper sourcing and stringent testing protocols are essential. This sector must reflect continuously on its practices to improve and adapt to modern challenges in medicine.

Importance of Raw Pharmaceutical Materials in Medicine

This bar chart illustrates the importance of various types of raw pharmaceutical materials in the pharmaceutical industry. Active Pharmaceutical Ingredients (API) play the most significant role, followed by Excipients, Biologics, Botanical Extracts, and Synthetic Intermediates.

The Role of Quality Control in Raw Pharmaceutical Production

Quality control in raw pharmaceutical production is crucial for ensuring safety and efficacy. Each raw material must undergo rigorous testing. This process helps identify impurities or variations in quality. When the quality is compromised, the effects can be severe. Health risks may arise from contaminated or substandard products.

Quality control also ensures compliance with regulatory standards. However, some facilities still struggle with maintaining these standards consistently. The potential for human error exists at every stage. Equipment may malfunction, leading to inaccuracies in measurements. Regular audits and trainings can help improve these issues.

Maintaining a high-quality production environment requires diligence. Companies need to invest in advanced technologies for better monitoring. Workflows should be streamlined, reducing the chances of oversight. Workers must be well-trained to recognize potential quality issues. Only with a proactive approach can the industry mitigate risks effectively.

Market Trends: The Global Demand for Raw Pharmaceuticals in Healthcare

The global demand for raw pharmaceuticals is witnessing significant growth. This trend is driven by an increasing focus on health and wellness. More people are seeking preventive healthcare solutions. As a result, manufacturers face rising pressure to provide high-quality raw materials. These are essential for producing effective medications.

Countries worldwide are ramping up their production capabilities. Emerging markets show a particularly strong appetite for raw pharmaceuticals. Many healthcare systems struggle with supply chain issues, raising questions on sourcing and sustainability. Companies need to ensure transparency in their supply chains as consumers are becoming more educated and selective about product ingredients.

Innovation in this sector is crucial. New extraction technologies are improving efficiency and potency. However, there's still a long way to go in standardizing quality control. Many raw materials vary significantly in purity levels. It's vital to address these inconsistencies to build trust. For the future, achieving a balance between demand and quality will remain a serious challenge for the industry.

Related Posts

-

The Ultimate Guide to Sourcing the Best Pharmaceutical Materials for Global Procurement

-

Discovering Reliable Supply Chains for Drug Raw Materials in a Competitive Global Market

-

How to Choose the Best Drug Raw Material for Your Pharmaceutical Needs?

-

Understanding the Importance of Drug Raw Materials in Modern Pharmaceutical Development

-

Unlocking the Future of Healthcare with Innovative Pharmaceutical Materials

-

How to Source High Quality Pharmaceutical Raw Material for Your Business